Manually retracting a hydraulic slide-out involves locating the hydraulic motor, using a manual override crank, and physically pushing the slide in. Ensure power is disconnected, wear protective gear, and follow manufacturer-specific instructions for safe operation.

Understanding the Basics of Hydraulic Slide-Out Systems

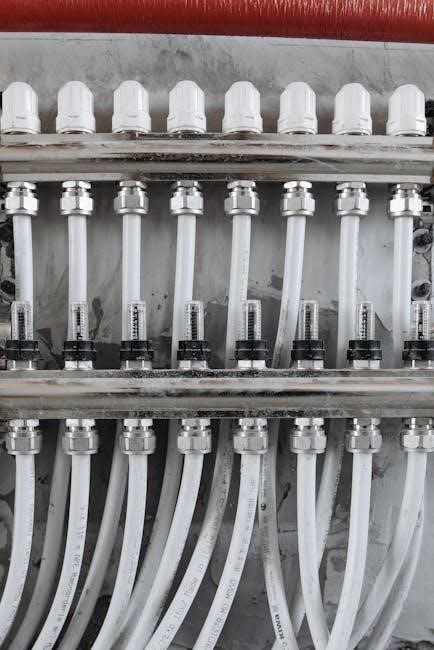

Hydraulic slide-out systems rely on pressurized hydraulic fluid to extend and retract components like RV slides. These systems typically include a hydraulic pump, motor, and cylinders that work together to facilitate smooth operation. The pump generates pressure, which is then transmitted to the motor and cylinders, enabling the slide-out to move in or out. Understanding how these components interact is crucial for diagnosing issues and performing manual retraction when necessary. Hydraulic systems are known for their power and reliability but can malfunction due to leaks, low fluid levels, or electrical failures. Familiarizing yourself with the system’s layout and operation will help you address problems effectively. Always refer to your RV’s manual for specific details about your slide-out system, as designs may vary between manufacturers. Regular maintenance, such as checking hydraulic fluid levels and inspecting hoses, is essential to ensure optimal performance and prevent unexpected breakdowns. This foundational knowledge is key to safely and efficiently managing your hydraulic slide-out system.

Essential Tools and Equipment Needed

To manually retract a hydraulic slide-out, gather essential tools and equipment; A manual override crank wrench is crucial for operating the hydraulic motor without power. A screwdriver or wrench may be needed to access components. Protective gear like gloves and safety glasses is important to prevent injury. Ensure you have a supply of hydraulic fluid and a pump, if applicable. Some systems require opening manifold valves, so a valve-opening tool may be necessary. A flashlight can help illuminate dark spaces, and blocking materials like wooden planks can stabilize the slide during retraction. Consult your RV’s manual for specific tools recommended by the manufacturer. Having these items ready will streamline the process and minimize risks. Organize your tools beforehand to avoid delays. Remember, manual retraction is labor-intensive, so ensure you’re prepared physically and with the right equipment. This preparation is vital for safely and effectively retracting your slide-out when hydraulic power is unavailable.

Preparing for Manual Retraction

Before manually retracting your hydraulic slide-out, ensure the RV is on level ground using leveling jacks or blocks. Clear the area around the slide-out, both inside and outside, to avoid obstructions. Disconnect the power supply to the hydraulic system and ensure the battery is switched off for safety. Apply silicone-based lubricant to moving parts to reduce friction. Gather assistance, as manual retraction can be physically demanding. Review the owner’s manual for specific instructions related to your RV model. Ensure all loose items near the slide-out are secured to prevent damage. Check for any hydraulic fluid leaks and address them before proceeding. Finally, wear protective gear, such as gloves and safety glasses, to protect yourself during the process. Proper preparation ensures a safer and more efficient manual retraction of your hydraulic slide-out.

Locating the Hydraulic Motor and Control System

The hydraulic motor and control system are typically located beneath the RV, often near the entry steps or in the underbelly compartment. To access these components, you may need to remove protective panels or storage bins. Refer to your RV’s owner’s manual for exact locations, as they can vary depending on the model and manufacturer. The hydraulic motor is usually connected to an extension rod or cylinder that powers the slide-out mechanism. The control system, including valves and pumps, is often housed in a central hydraulic hub. To locate these, look for hydraulic lines and connections near the slide-out’s base. Ensure the system is turned off and the battery is disconnected before attempting to access or manipulate these components. If you’re unsure, use a flashlight to illuminate the area and consult a professional if needed. Proper identification of these parts is crucial for safe and effective manual retraction.

Steps to Manually Retract Hydraulic Slide-Out

- Open the Manifold Valves: Locate and open the hydraulic manifold valves to release pressure in the system. This step is essential to allow manual operation of the slide-out mechanism.

- Disconnect Power: Ensure the hydraulic system is turned off and the battery is disconnected to prevent accidental activation.

- Attach the Manual Override Tool: Use the provided or purchased manual override crank to connect to the hydraulic motor or gear pack. This tool allows you to control the slide-out manually.

- Operate the Crank: Turn the crank clockwise to retract the slide-out. This process may require significant effort, as hydraulic systems are designed to handle heavy loads.

- Physically Assist the Slide: If the slide does not move easily, carefully push it inward while operating the crank. Ensure the slide is properly aligned to avoid damage.

- Secure the Slide: Once fully retracted, use locking mechanisms or stabilizers to hold the slide in place for safe travel or storage.

Remember, manual retraction is a labor-intensive process and may require assistance. Always prioritize safety and avoid forcing the slide, as this could cause system damage.

Specific Instructions for LCI Hydraulic Systems

For LCI (Lippert Components Incorporated) hydraulic systems, manual retraction requires specific steps. First, locate the hydraulic control panel, typically found near the power center or under the RV. Next, switch the system to manual mode by toggling the appropriate switch or releasing the solenoid. This disengages the automatic controls, allowing manual operation.

Attach the manual override crank to the hydraulic motor. Insert the crank into the designated socket and ensure it is securely locked in place. Gently but firmly turn the crank clockwise to begin retracting the slide-out. Monitor the slide’s movement, applying additional force if necessary, but avoid overexertion;

Once the slide-out is fully retracted, engage the manual lockout mechanism to secure it in place. This prevents accidental extension during travel. Finally, check the system for any leaks or damage before restoring power or moving the RV. Always refer to the LCI owner’s manual for model-specific instructions.

Special Considerations for Schwintek Slides

Schwintek slides operate using an electric motor connected to a worm gear system, which can be challenging to manually retract. If the motor fails, you’ll need to access the gear system directly. Start by disconnecting the battery to ensure safety. Locate the motor and gear assembly, typically found near the slide-out mechanism. Remove any covers or panels to access the gears. Use a wrench to manually turn the worm gear counterclockwise, which will retract the slide. Be cautious, as this process can be labor-intensive. If the slide is stubborn, apply gentle force but avoid excessive pressure to prevent gear damage. Once retracted, secure the slide with manual locks or brackets to keep it in place. Always consult the Schwintek manual for specific instructions, as some models may vary. After manual retraction, inspect the system for any damage or misalignment before restoring power or operation. This ensures smooth functionality in the future. Proper maintenance is key to avoiding repeat issues.

Safety Tips and Precautions

When manually retracting a hydraulic slide-out, safety is paramount. Always disconnect the power supply, including batteries, to prevent accidental activation. Wear protective gear such as gloves, safety glasses, and sturdy footwear. Ensure the area around the slide is clear of obstacles and people. Never attempt manual retraction under load or with weight inside the slide, as this can cause structural damage or injury. Use approved tools, like a manual override crank, and avoid improvising with unapproved equipment. If the slide is stuck, apply gentle, consistent pressure rather than force, which might damage components. Be aware of fluid leaks, as hydraulic systems can release pressurized oil. Keep rags handy to clean spills and prevent slipping hazards. If unsure, consult a professional to avoid risks. Proper ventilation is essential when working with hydraulic systems to prevent inhaling fumes. Always follow the manufacturer’s guidelines and consider having a second person assist for safety and support. Regularly inspect the system after manual retraction to ensure stability and functionality. Prioritize caution to protect yourself, your RV, and others nearby. Stay informed and prepared for any unexpected challenges during the process. Proper safety measures ensure a safe and effective manual retraction process.

Maintenance and Troubleshooting After Manual Retraction

After manually retracting your hydraulic slide-out, it’s crucial to perform thorough maintenance and troubleshooting to ensure optimal functionality. First, inspect the hydraulic system for any leaks or damage, especially around cylinders and hoses. Check the fluid levels in the hydraulic tank and top them off if necessary, using the manufacturer-recommended fluid type. Inspect the slide’s alignment and ensure all gears and mechanisms are properly engaged. Clean any debris or dirt that may have accumulated during the manual process. Test the slide’s automatic operation to confirm it’s functioning correctly. If issues persist, such as slow movement or jerking, check for air in the hydraulic lines, which may require bleeding. Lubricate moving parts to prevent corrosion and wear. Regularly service the hydraulic pump and motor to maintain efficiency. If you encounter problems like stuck slides or unusual noises, consult the owner’s manual or contact a professional technician. Addressing these issues promptly prevents further damage and ensures smooth operation in the future. Proper maintenance extends the lifespan of your hydraulic slide-out system. Stay proactive to avoid costly repairs and enjoy reliable performance. Consistent upkeep is key to maintaining your RV’s functionality and safety.